Description

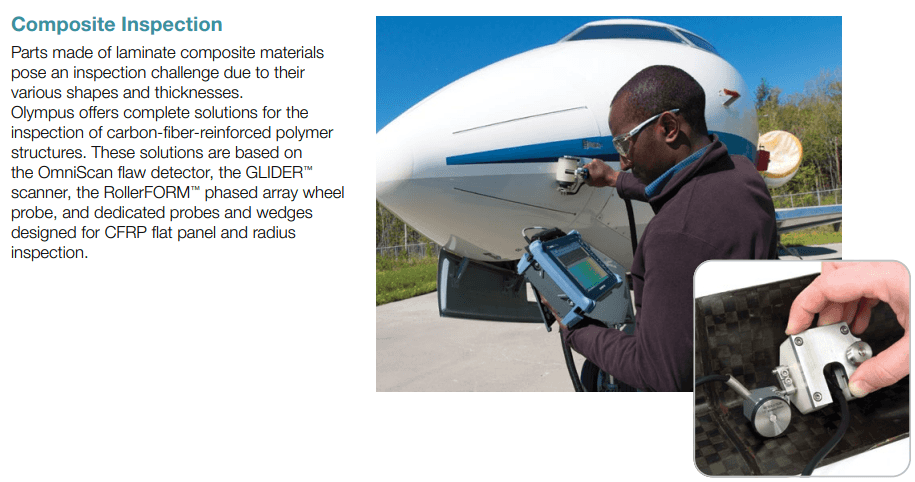

The Olympus OmniScan MX Ultrasonic Flaw Detector is a portable tool designed for flaw detection. It has a high acquisition rate and can perform ultrasound, phased array, and eddy current inspections.

Technicians rent this device for many tests. It can perform TOFD, pulse-echo, o-degree, c-scan, and various eddy current and phased array tests. These tests are used in avionic and military applications.

The Olympus OmniScan MX has a built-in connector. This connector identifies the connected probe. It automatically sets the probe to the right frequency. This helps reduce the risk of damaging the probe.

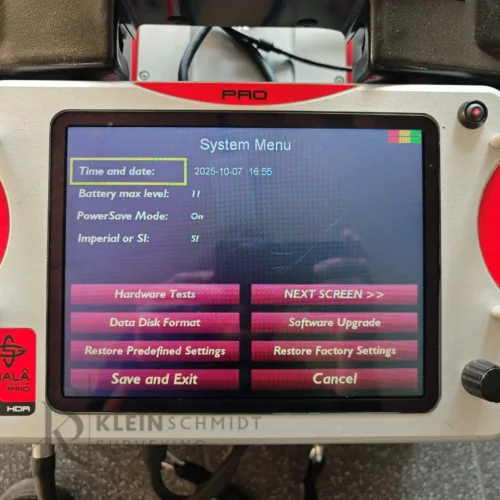

The Olympus OmniScan MX models display your test results on a 21 cm LCD screen with a resolution of 800 x 600 pixels. They store data using a CompactFlash card or a standard USB storage device. These models provide at least 6 hours of run time with two batteries.

The Olympus OmniScan MX2 16:128 offers high-resolution imaging for critical inspections.

The OmniScan MX2 16:128 enhances flaw detection accuracy and streamlines workflows, making it indispensable in multiple industries.

The second-generation OmniScan MX2 boosts testing efficiency. It ensures better performance for advanced AUT applications. Setups, test cycles, and reporting are faster. It also works with many phased array and ultrasound modules.

Designed for NDT experts, this high-end, scalable platform delivers true next-generation NDT performance. The OmniScan MX2 has a fast acquisition rate. It also includes new software features for better manual and automated inspections. This all comes in a portable, modular instrument.

The OmniScan MX2 streamlines setup for easier and faster operation. It’s a simple step-by-step Wizard that helps you start testing quickly.

Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in. The MX2 features a 26.4 cm screen and new touchscreen capabilities. It also offers faster data transfer. This helps you reach your next inspection more quickly.

Key Advantages:

- No need for paint removal.

- Imaging and archiving.

- One-step inspection, high scan speed, and instant results.

- Major time-savings (typically 10:1 and over).

- Drastically reduced turnaround time.

- Defect depth evaluation capability.

- Adjustable sensitivity and post-process analysis.

- Environment-friendly method (no chemicals involved).

Key Features:

- Conducts bond testing C-scans, TFOD tests, and more

- Simplifies eddy current array / phased array testing

- Combines ECA and ECT units

- Portable, modular

- Variety of data storage options

- Large high-resolution screen

- Capable of analysis and archiving

Applications

Inspection Capabilities:

- Girth Weld Inspection

- Pressure Vessel Weld Inspection

- Scribe Marks Inspection with No Paint Removal

- Aircraft Fuselage Inspection

Ultrasound Inspection:

- Time-of-Flight Diffraction Testing

- TOFD and Pulse-Echo Testing

- 0-Degree Testing (Corrosion and Composite)

- Ultrasound Transducers

Phased Array Inspection:

- Phased Array Probes

- Angle beam probes with external wedges

- Angle beam probes with integrated wedge

- Immersion probes

Eddy Current Inspection:

- Eddy Current Probes

- Bolt hole probes

- Surface probes, in various shapes and configurations

- Low-frequency spot and ring probes

- Sliding probes

- Wheel probes

- Conductivity probes

- Specialty probes made for specific applications

The OmniScan MXA Field-Proven, Dependable Instrument

Thickness and Flaw Inspection Solutions

The OmniScan® MX is a reliable tool used worldwide. It has thousands of units in use. This instrument is designed to handle tough inspection conditions. Compact and lightweight, its two Li-ion batteries provide up to 6 hours of manual or semi-automated inspection time.

The highly legible 8.4 in. (213 mm) real-time color display of the OmniScan MX enables you to see defects and details under any light conditions. Use the instrument’s easy interface with the scroll knob and function keys. You can also connect a USB mouse to help with the inspection analysis.

Please note that product availability varies by region. Contact your local Evident sales office for more information.

ECA is just like ECT: Large Coverage, Fast Scanning, and Higher Probability of Detection

Eddy current array (ECA) technology uses multiple traditional bridge or reflection probe coils. This allows for larger coverage in one inspection pass.

Each ECA probe model is made to detect specific defects. It works well along the whole length of the probe. With the OmniScan MX ECA, you can utilize ECA probes at fast manual inspection speeds, providing a powerful and productive inspection experience with color representation and archiving capabilities.

Instant Reporting and Easy Archiving

The OmniScan MX features built-in reporting at the touch of a key. Reports can also be configured and customized by advanced users. The factory-default report format includes a screenshot and chosen data fields. This design aims to reduce the need for customization.

You can easily archive inspection data files. At any time, whether during acquisition or analysis, just press a key. This will instantly save the data to the instrument’s memory card.

Perform data analysis quickly and efficiently with mouse input—archive files to a PC with the help of a CompactFlash reader.

Included with Sale

- -Omniscan MX2 Main Unit

- -Omniscan MX2 16:128 P2 Module

- -Hard Padded Transport Case

- -Lithium Ion Battery

- -Charger and AC Cable

- -Calibration Paperwork

- -User Manual

- ** unit is under calibration until September 2025